Air Compressor

Air compressor is a kind of equipment that converts mechanical energy into gas pressure energy, and is a necessary equipment in any CIL plant.

Model: Roots series; Screw series

Common types of Air Compressor in CIL Process

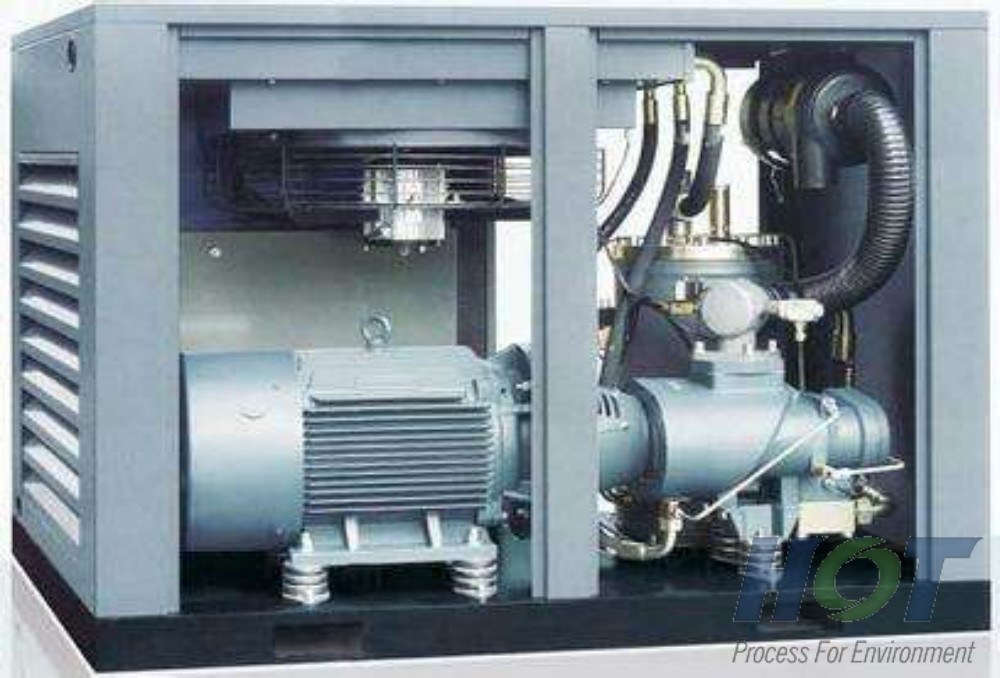

Screw compressor, It is a kind of rotary volume compressor. There are two interlocking gears with helical gears inside, so that the volume of the two rotor meshes decreases from large to small, thus compressing and discharging the gas.

Roots double rotor air compressor, it is also a kind of rotary volume compressor, in which two roots rotors engage each other and intercepted gas and send them from the intake to the vent. There is no gas compression process inside it.

Usually, the compressed air required in the CIL plant is low pressure and large flow, large scale CIL plants usually use screw air compressor, and the screw air compressor exhaust pressure is usually more than 0.3Mpa which is higher than the required pressure(0.09-0.12 Mpa), so it is necessary to be equipped with a step-down valve. The roots blower is widely used in small scale CIL plants

The Difference of The Two Common Types Air Compressors

The Roots air compressor can provide bigger air flow, but pressure is lower;

Due to the special sealing performance, exhaust air of roots’ is cleaner than screw compressor;

Due to the structural characteristics, while working,screw has smaller vibration, smaller noise, and few wear and tear of the components, which contribute it can long and continues work.