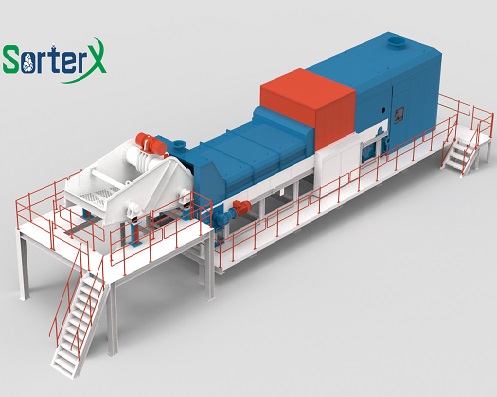

Belt Conveyor

Belt conveyor is a continuous operation of transportation equipment, it is an indispensable equipment in the CIL plant.

Working Principle

Belt conveyor is composed by two endpoint pulleys and a closed conveyor belt. The pulley that drives conveyor belt rotating is called drive pulley or transmission drum; the other one–only used to change conveyor belt movement direction–is called bend pulley. Drive pulley is driven by the motor through reducer, and conveyor belt dragging relies on the friction drag between the drive pulley and the conveyor belt. The drive pulleys are generally installed at the discharge end in order to increase traction and be easy to drag. Material is fed on the feed-side and landed on the rotating conveyor belt, then rely on the conveyor belt friction to be delivered to discharge end.

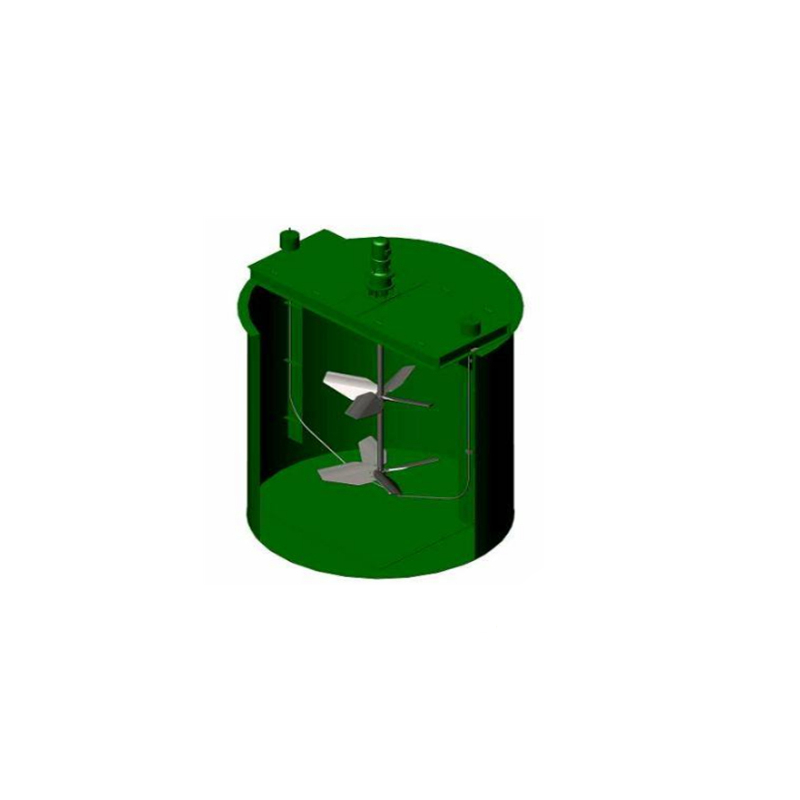

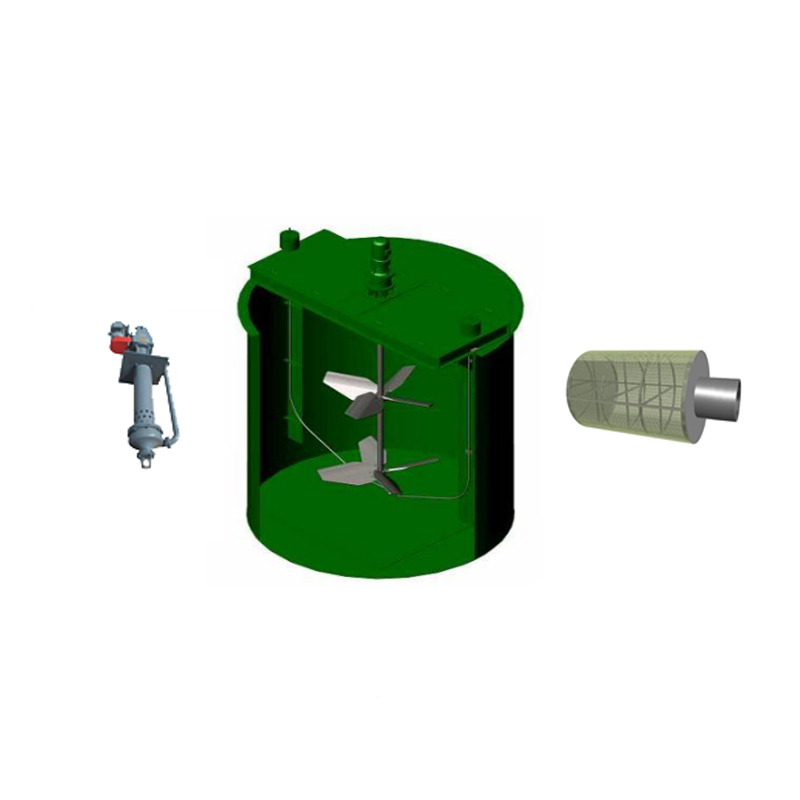

Main components

Driving device, mainly composed of motor, hydraulic coupler, reducer, coupling and so on;

The vertical tightening device is mainly composed of the upper and lower bend pulley and counterweight drum, so as to make the whole belt is in a tight state;

Roller assembly, it is a component that supports the belt and the material above it;

The sweeper, including the head sweeper and the empty section sweeper. Its function is to make the materials bonded on the belt shedding in a specified place;

Belt protection device, including anti tearing, under speed protection, comprehensive protection, anti blocking, anti running deviation, pulling rope, emergency stop and other protective devices;

What can HOT Provide

With excellent R & D strength and manufacturing skills, HOT can provide different width and length belt conveyor for clients all over the world. We can provide the customized service for different customer demands.

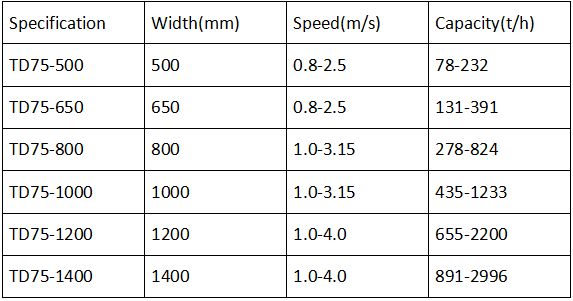

Partial Technical Parameters of Belt conveyor

The capacity is calculated by the following data,material's loose density is 1.0t/m, conveyor angle is 0-7°, The accumulation angle of the material is 30°

The form of the roller in the upper table is the groove roller.