Three-Stages SKT Baum Jig Washer’s Industrial Application Advantages

Recently in coal washing industry, two-stages SKT Jig Washers are widely applied. The separation efficiency is only at about 70% when treating R.O.M with high ash and poor quality.

As the on-going implementation of Energy Conservation and Emission Reduction Policy as well as Coal Cleaning Technology Strategy, coal washing obtains great attention, washing proportion gets higher per year. However, due to fierce competition among coal concentrate products and continuing industry depression, it’s getting more and more important to choose coal washing machine with high quality and good performance.

To meet the demand of market, HOT Mining research and developed SKT-12 model Three-Stages Jig Washer on the basis of existing two-stages jig washer. The SKT-12 model Three-Stages Jig Washer can realize the advantages of three-stages jigging, and supported with secondary coal concentrate middling back washing process, which can meet requirement of improving final coal concentrate quality and quantity, it can increase coal concentrate recovery by at least 2%.

Ⅰ Working Principle and Structure of SKT-12 Three-Stages Jig Washer

1. Working Principle

The R.O.M is fed onto screen panel of jig washer from feeder and forms dense material layer. The air valve inputs compressed air into underscreen chamber by turns, and discharges compressed air out by certain rules. When inputs compressed air, the water in jig washer is forced to ascend; after the compressed air discharged from air chamber, the water level descends automatically, the pulsating flow is formed when water in jig room goes through screen panel up and down, R.O.M is layered according to density under the function of pulsating flow, and is divided into 4 kinds of products by discharge mechanism, coal concentrate, secondary coal concentrate, middling and reject.

2. Main Structure

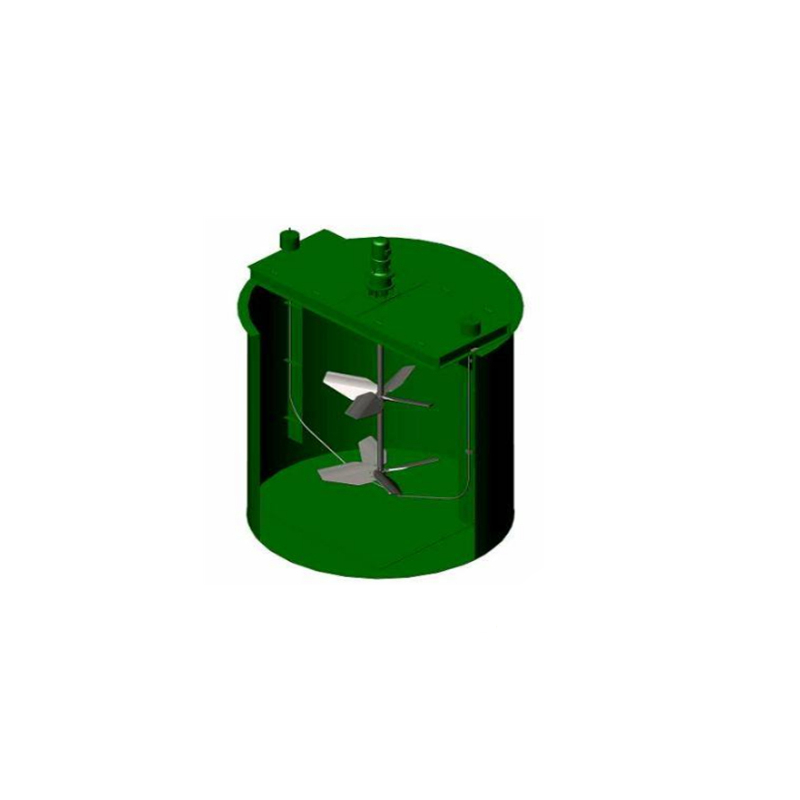

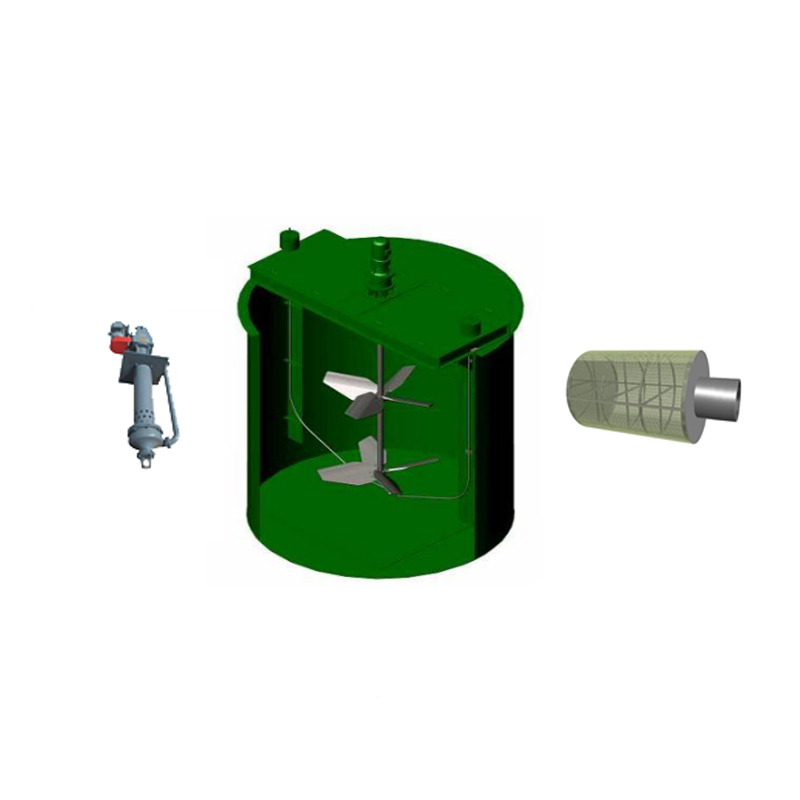

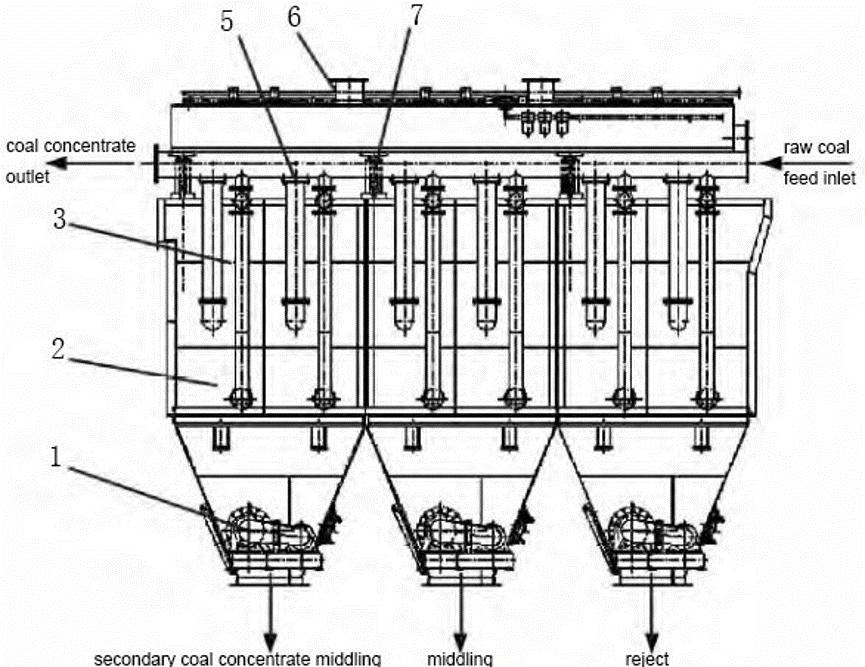

SKT-12 model Three-Stages Jig Washer mainly consists of machine body, air valve, discharge device, screen panel and floater (please refer to Figure 1). Each units are connected by bolts and welding method, to form a whole jig washer.

1-Discharge device

2-Machine body

3-screen panel

4-Air valve

5-Butterfly valve

6-Floater 7-Gate

Figure 1 - Schematic diagram of SKT-12 Three-Stage Jig Washer Structure

2.1 Machine Body

The function of machine body is to bear whole weight of jig washer and the dynamic load generated by pulsating flow. It’s welded by steel plate, and is divided into three stages vertically. Each stage is divided into 2 compartments, in each compartment there’s air chamber, air valve and topwater piping. Each air chamber in compartment is designed to be underscreen chamber, which can make wash water vibrate in U shape. The deflector has streamlined design, and the spigot is funnel-shaped.

2.2 Air Valve

Air Valve is crucial device of jig washer, it controls air chamber’s connection with gas distribution room and air periodically, creates inlet and outlet, thus the wash water can pulsates reasonably, which finally makes material ideal loose layering.

The SKT-12 Jig Washer adopts technology by sharing air valves among chambers, simplifies air valves from traditional 12 pcs to 6 pcs, each stage is outfitted one inlet valve and one outlet valve. The inlet valve is placed at low-pressure area, the gas distribution room can be connected with low-pressure area when open, thus the low-pressure air can enter air chamber by gas distribution room. The outlet valve is placed at exhausting area, it can connect air distribution room when open, the air can enter into air chamber by gas distribution room and be exhausted from exhausting area. Two valves work alternately to control pulsation of wash water.

2.3 Discharge Device

The material is layered inside the jig washer after many times’ pulsations, material density on the bed increases gradually from top to bottom. The discharge device discharges material with different density respectively, in order to ensure each stage’s product quality and yield.

2.4 Screen Panel & Floater

The screen panel of jig washer supports material and forms material layering space with machine body. The screen panel also has function of controlling screening discharge velocity and heavy fraction movement velocity in horizontal direction.

The SKT-12 model Three-Stages Jig Washer uses obconical punching screen panel, obconical aperture is good for fraction screening, not easily jammed and convenient in cleaning, which can ensure coal concentrate product quality. In the model illustrated in this paper, first stage screen panel angle for reject is 3°, second stage screen panel angle for middling is 1°, third stage screen panel angle for coal concentrate is 1°.

The floater is used for detecting thickness of material bed layers, and transmits detection data to control cabinet from sensor, controls rotation velocity of discharge pulley, thus to sustain normal material layering condition.

Ⅱ Analysis of SKT-12 model Three-Stages Jig Washer’s Industrial Application Advantages

1.Structural Advantage

One important factor which affects coal concentrate separation efficiency in jig washer is separation time and frequency. Proper extension of material separation time in jig washer can make more adequate layering and avoid mixture among materials. Increase separation frequency properly can ensure final coal concentrate product’s quality, by many times layering, discharging and selecting concentrate from concentrate.

Compared with traditional two-stages jig washer, three-stages jig washer improves by 1.5 times no matter on separation time and frequency, which benefits final coal concentrates quality and yield.

Under the premise that other factors affecting jigging performance are same, for easy-separation coal, the ash content in final coal concentrate of three-stages jig washer is similar to two-stages jig washer’s; however, for hard-separation and ultra-hard-separation coal, separation effect of three-stages jig washer is significantly better than two-stages’, of which the ash content in coal concentrate is 10%~15% lower.

2. Technical Advantages

2.1 Secondary separation of secondary coal concentrate middling

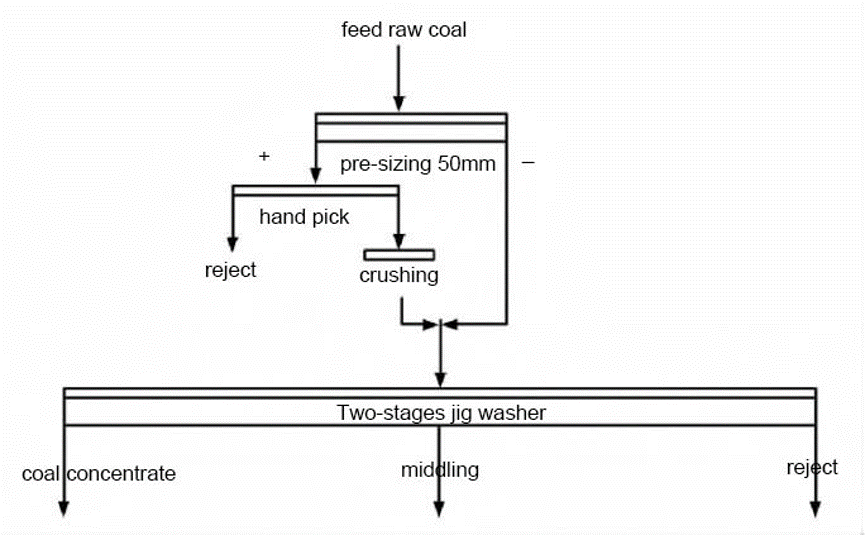

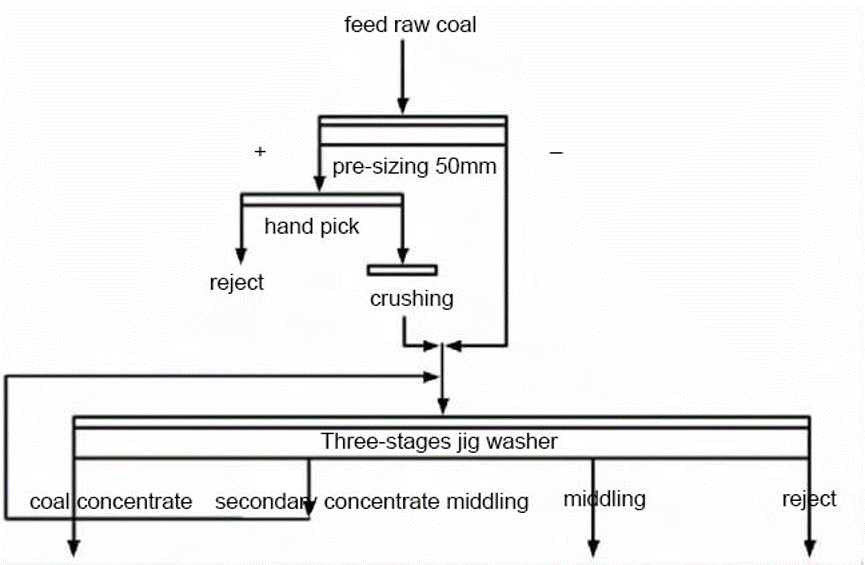

Different from traditional two-stages jigging separation process (please refer to Figure 2 and Figure 3), the three-stages jig washer produces another product named secondary coal concentrate middling. In coal industry, we name the middling as secondary coal concentrate middling, which contains more concentrate and is worthy re-washing and recycling.

The concentrate content in secondary coal concentrate middling is about 10%~15%, which takes up 1% in total feed raw coal, and about 1.7%~2% in total coal concentrate. When treating hard-separation coal, three-stages jig washer rewashes secondary coal concentrate middling (please refer to Figure 3) to improve the coal concentrate recovery rate, and avoid loss of concentrate.

Figure 2 - Flowchart of two-stages jig washer

Figure 3 - Flowchart of three-stages jig washer

2.2 Reducing whole separation process workload

Different from two-stages jig washer, three-stages jig washer can wash three times in three stages, and produces one more intermediate product-secondary coal concentrate middling, which can reduce following procedures’ coal concentrate yield, and finally relieve workload of flotation process and slurry system process.

Due to reduction of flotation workload, the float-feed amount and feed density is decreased, pulp entrainment gets relief; the material is floated significantly, which makes flotation process outcome better, and increase recovery of fine coal slime. Due to reduction of flotation coal concentrate and tailing, the workload of filtration process in slurry system is relieved, which is good for continuous production, and solve the problem of slurry system treatment delay, finally enhance whole coal washing plant’s capacity.

2.3 Advantage of product reliability

For coal washing industry, each equipment in coal washing plant works about 16 hours averagely per day, 330 days per year, thus the reliability of equipment is of great importance in whole industry.

By RAMS calculation in CAFTA software, the reliability of SKT-12 model Three-Stages Jig Washer is analyzed. From the result: the Mean Time Between Failure (MTBF) of jig washer is 1,11,200 tons, namely, the jig washer can run continuously for at least 60 days before failure occurs and maintenance is required, which is superior to other same kind product in market, and can ensure steady and continuous operation of coal washing plant.

3. Analysis of Economic Benefit

Designed raw coal feed capacity of Xuyong Coal Washing Plant is 0.9MTPA.

3.1 Coal Quality

Recovery rate of coal concentrate is 60%, middling is 18%, reject is 20%, coal slime is 7%.

3.2 Process Flow

By using SKT-12 model Three-Stages Jig Washer as main process equipment, coarse slime is recycled, fine slime is floated, thickened and filtrated.

From above we can know that the SKT-12 Three-Stages Jig Washer separates coal by three stages, and rewash coal by three stages, at last the coal concentrate recovery rate can be improved by 2% (which takes up 1.2% in total raw coal amount). With the application of SKT-12 Three-Stages Jig Washer, the yield of coal concentrate can be increased by 10,800 tons per year. In year 2015 the market price of coking coal concentrate in Sichuan Province is 700~800 Yuan per ton, raw coal price is 300~400 Yuan per ton. By calculating with 750 Yuan/ton coking coal concentrate, 350 Yuan/ton raw coal and 35 Yuan/ton operation cost, then the net profit can be increased by 1,409,400 Yuan per year for whole coal washing plant, and brings considerable economic benefit.

Alothough jig washer is a kind of process equipment which requires experienced and skilled operator, HOT Mining is still devoted to make better structural design to reduce failure possibility, and better coal concentrate recovery rate.What's more, we can help you to upgrade process and optimize the function of equipment.

Contact me for more:

Serena Fu

E-mail: serena.fu@hot-mining.com

Tel/WA:+86 15108333341

Tari Wang

E-mail: tari.wang@hot-mining.com

Tel/WA:+86 15927439651